Processing of beams with cross sections of 25 x 50 mm up to 240 x 360 mm, standard length up to 10 m. (longer or shorter on request)

For the production of outbuildings, carports, pool houses, roof sheds, timber frame construction, timber massif construction, roof structures, trusses, canopies, pergolas, prefabricated, awnings, tiny houses, house extensions, sheds, garden structures, stables, etc…

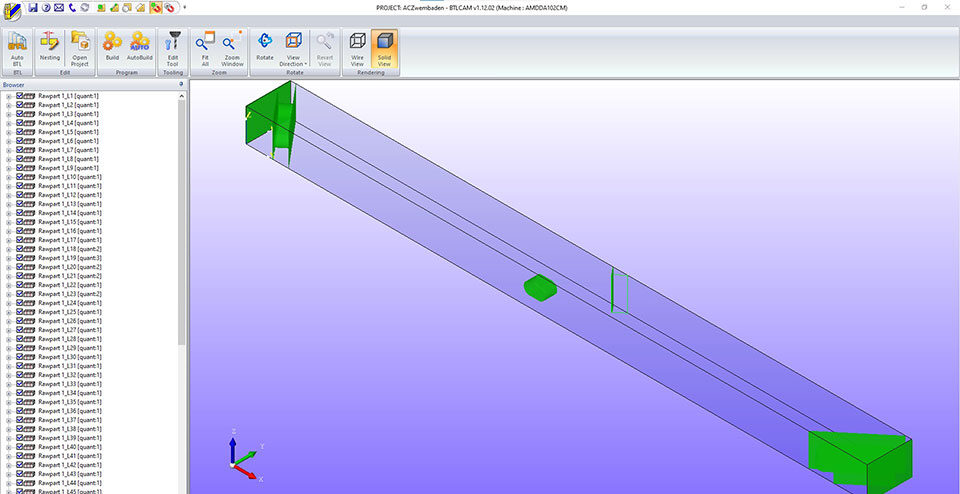

Machining a beam all-sided without far-reaching milling units which make it impossible to achieve a precise result. That is the challenge AMD was faced in its design.

The solution was found in the, meanwhile patented, machining method of the DA machine, where the beam rotates around its axis.

The result is an exceptionally wear-resistant and accurate machine.

The Do All machine is a multiple CNC machine that can deal with every imaginable machining operation on all six sides of the beam. One machine is sufficient to achieve a wide variety of machining operations, no matter how challenging.

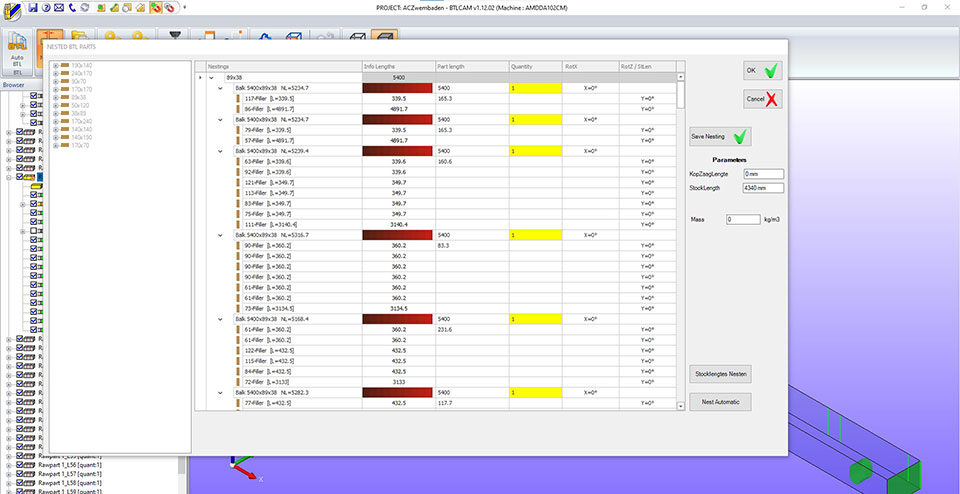

The Do-All machine is automatically programmed through BTL import. All you have to do is load the CAD model of the wood structure, and with a few clicks the machine program is generated. Spending hours programming machines and errors are things of the past.

There are no inaccurate roller conveyors and slipping drive systems.

AMD’s compact and innovative design means a machine length of 11,5 metres to process beams up to 10 m in length.

Machine supported by BTL import and automatic production optimisation.

Machine supported by BTL import and automatic production optimisation.