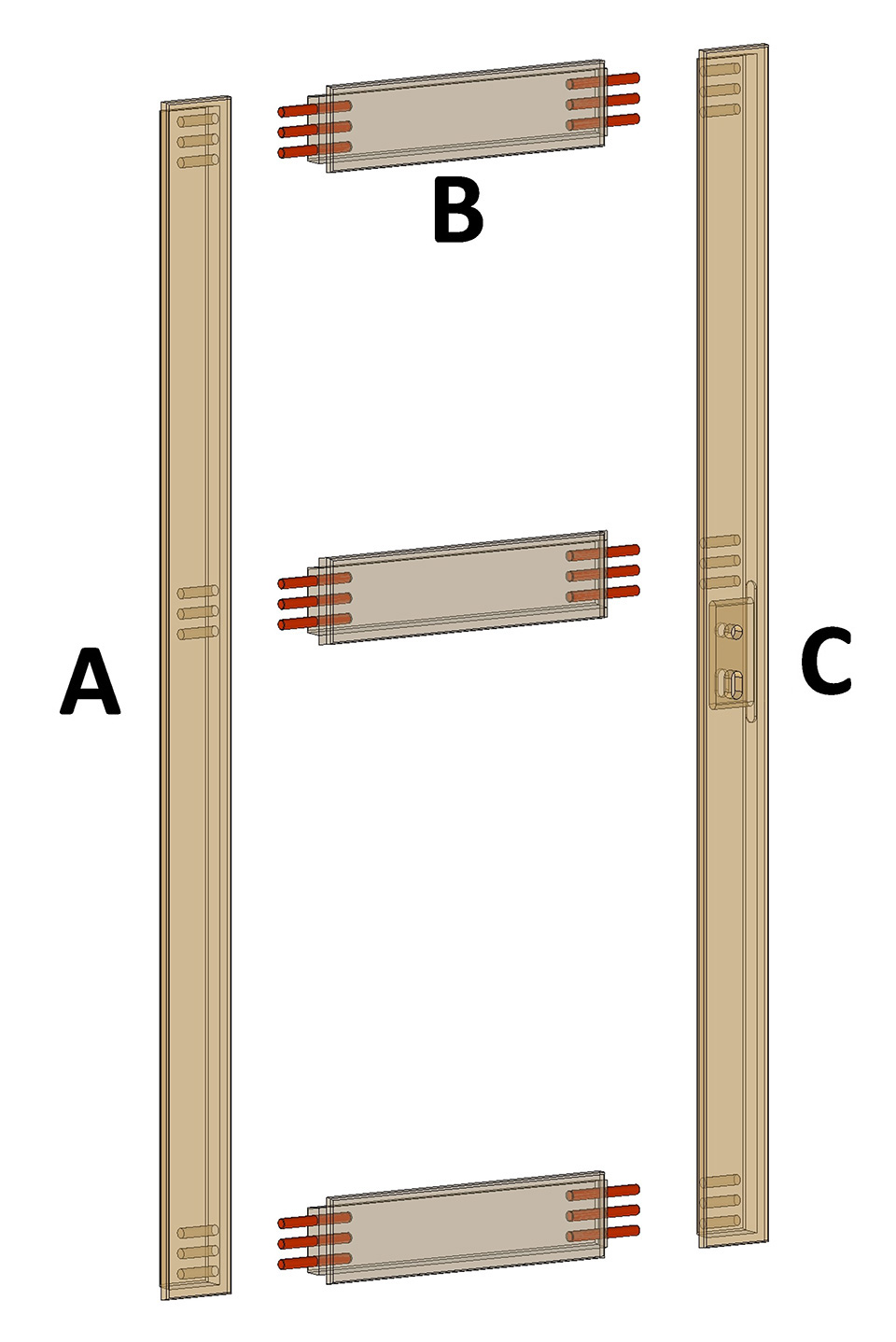

Processing of profiled beams.

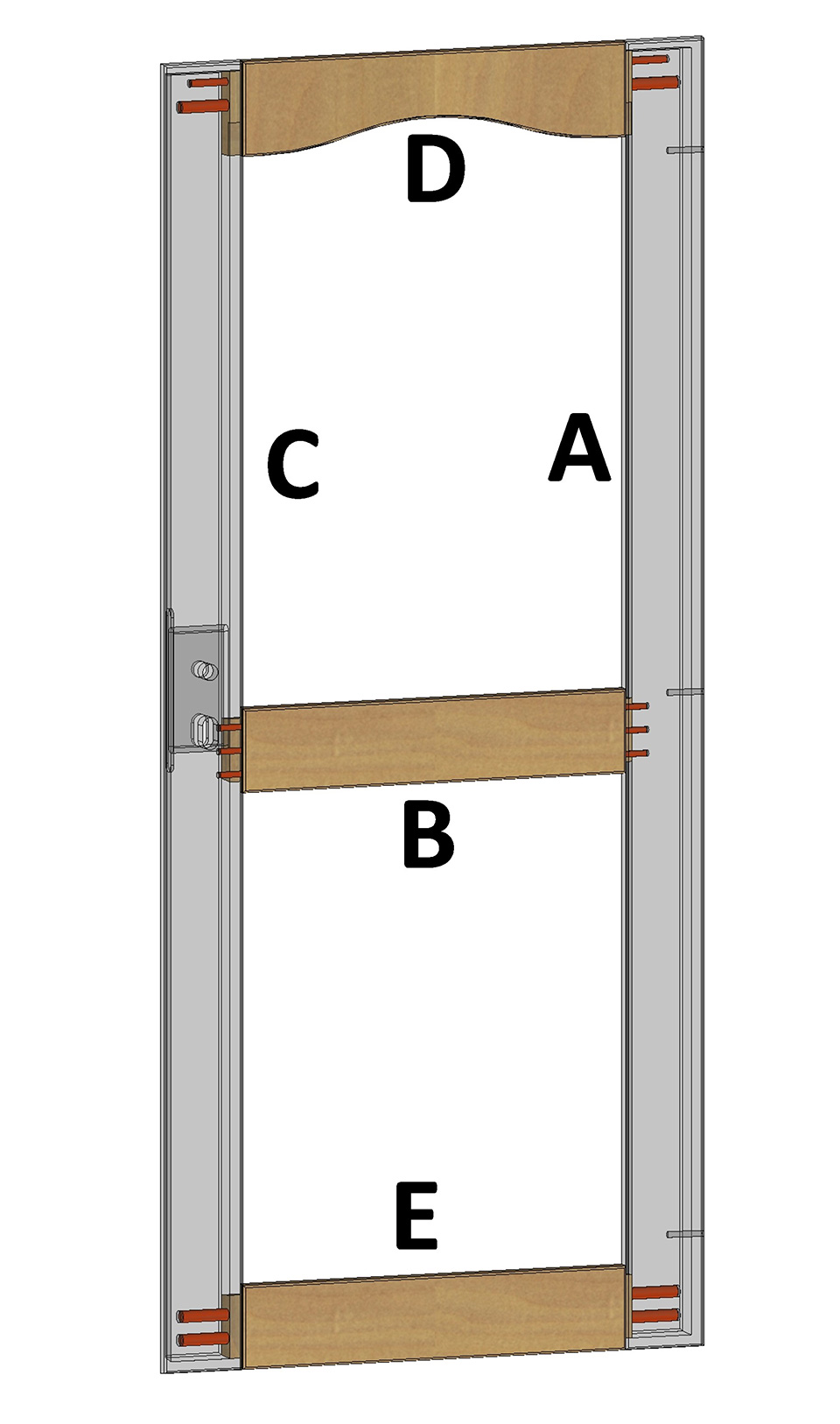

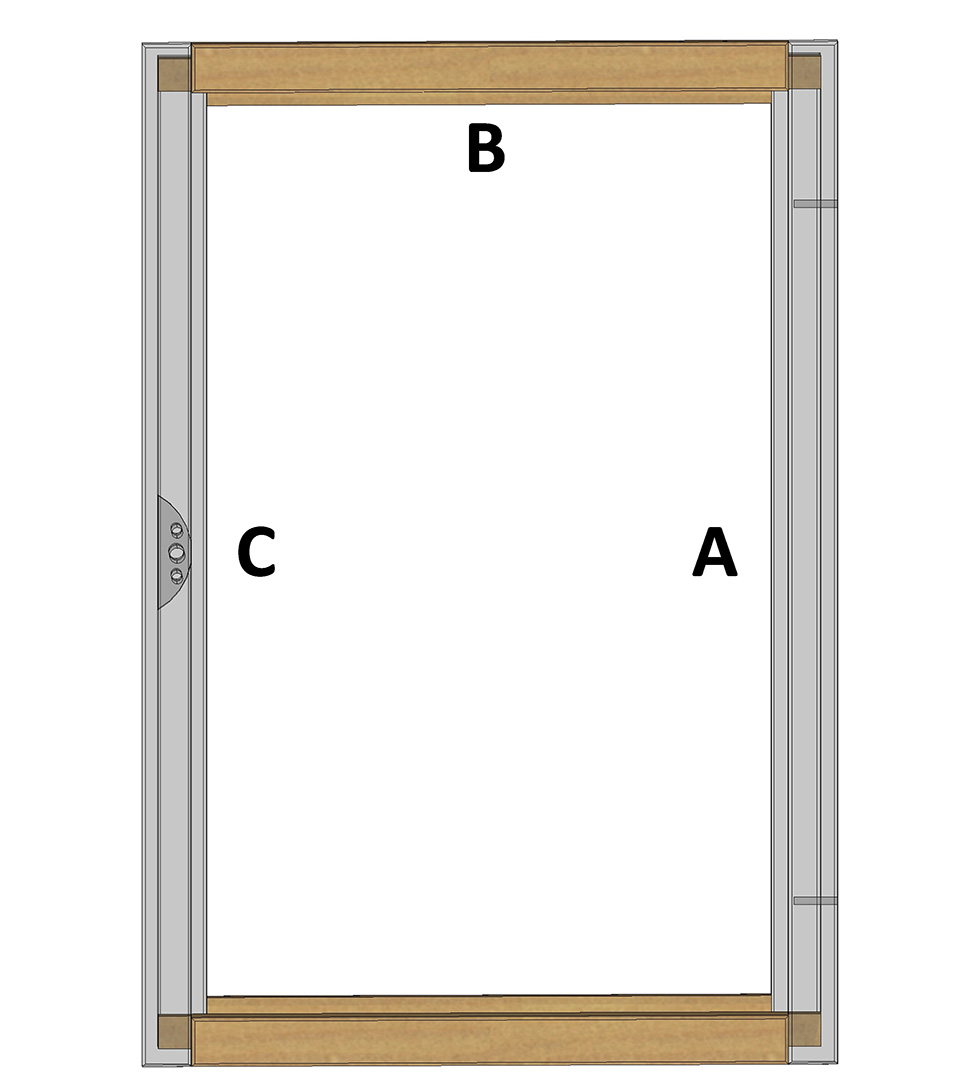

For the production of door and window elements for various buildings as chalets, log cabins, sheds, summerhouses, houses, …

AMD designed the DR machine based on techniques perfected through decades of experience in the furniture industry. This results in a machine with a unique process which produces door and window elements of furniture quality, at a blistering pace.