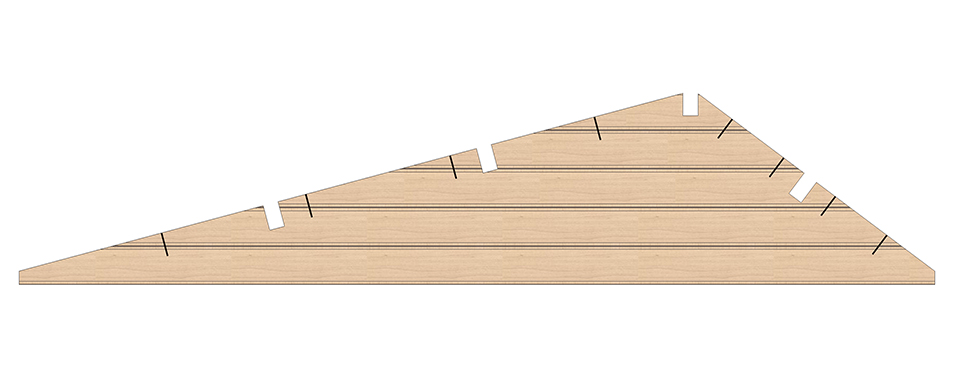

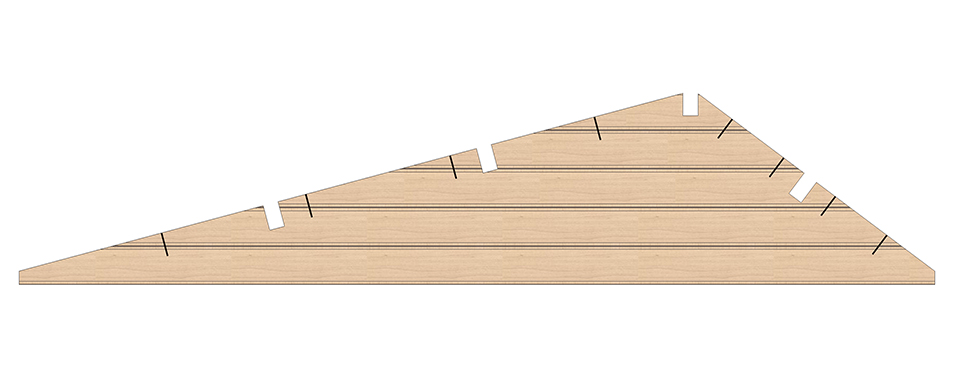

Processing of tongue-and-groove wall logs.

To produce gables for stacked log construction: chalets, log cabins, ….

Starting from a stack of wall logs. The machine saws the gable slope, notches and secures the gables with nails or screws. Time-consuming manual work, resulting in countless flawed gables, is a thing of the past.

The four-sided clamping, NC-controlled sawing unit and immediate securing of gables, ensure that such imperfections don’t occur when using the AMD TG machine.

With the TG machine a gable, with 4 notches for purlins, 28 mm thick logs, is manufactured in only a few minutes. The automated version, the speed is more more than halved.

Manual sawing makes it challenging to obtain perfectly straight gables. The TG machine, with its thorough, four-sided clamping in the machine guarantees that the cut has the desired shape.

With the automated TG machine a gable, with 4 notches for purlins, 28 mm thick logs, is manufactured in only a one minute.