Processing of beams with cross section up to 140 x 160 mm or 200 by 250 mm, length up to 6 m.

(Deviating dimensions on request.)

To produce log homes, outbuildings, gates, sheds, timber frame construction, pergolas, garages, shade structures…

For the production of outbuildings, fences, carports, pool houses, sheds, play equipment, swimming pools, wood massifs, pergolas, awnings, tiny houses, house extensions, storerooms, garden structures, stables…

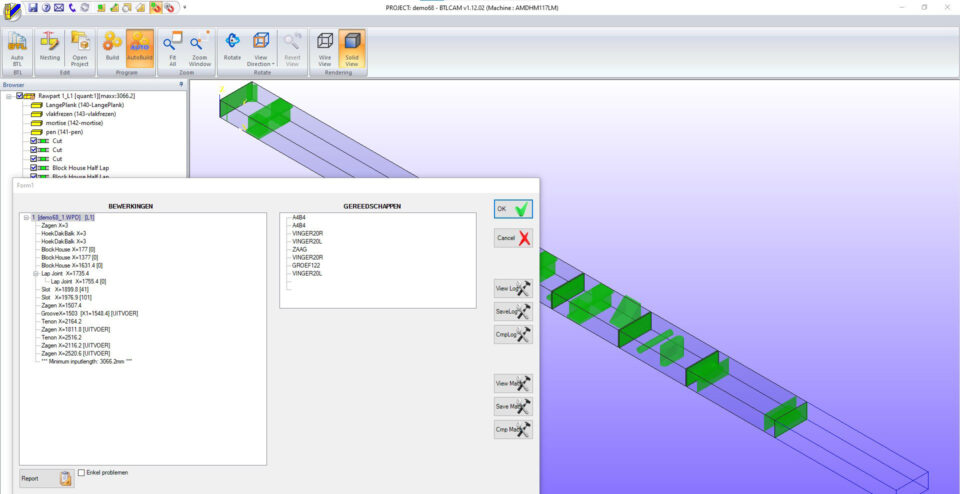

The unique concept of the HM machine allows a wide variety of operations to be performed on all sides of the beam. This makes the HM machine the machine of choice where high productivity and product flexibility are important.

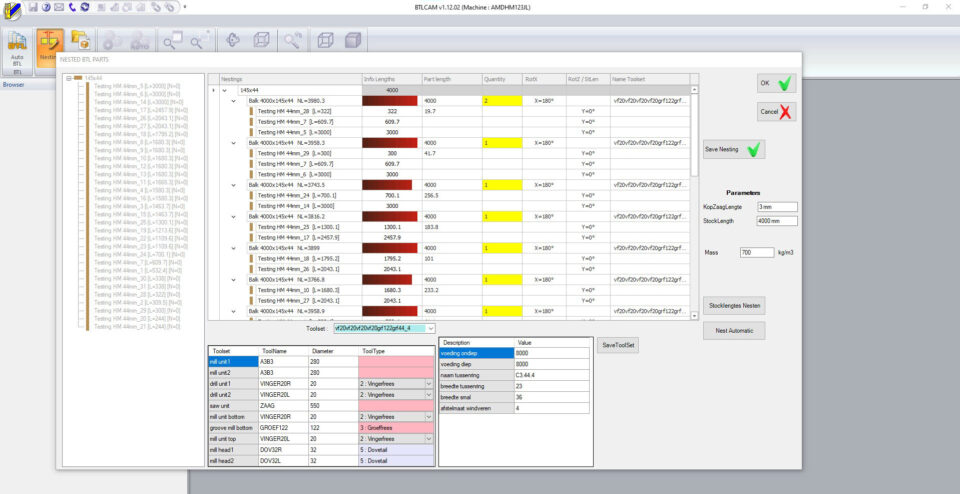

The HM machine is automatically programmed through BTL import. All you have to do is load the CAD model of the wood structure into the program and with a few clicks, the machine program is generated. Spending hours programming machines is a thing of the past.

With a machining compartment less than one meter in width, the HM machine sets the standard for well-thought-out, compact machine design. Furthermore, the fully closed and dust extracted machining compartment ensures a low-noise and dust-free healthy working environment.

Machine supported by BTL import and automatic production optimisation.

Machine supported by BTL import and automatic production optimisation.