Processing of wall logs, 18 mm to 70 mm thickness, up to 170 mm height and length up to 6 m or longer.

(deviating dimensions on request.)

For stacked log construction: log cabins, chalets, sheds, garden buildings …

The PI machine is used by all leading log building manufacturers in Europe. The unmatched production speed and huge reliability have made this machine industry’s trusted partner for more than 25 years already.

Starting from profiled wall logs, the PI machine manufactures finished wall logs that can be put right into the package.

The machine can be programmed through BTL import. All you have to do is load the CAD model of your wood structure into the program and with a few clicks, the machine is programmed. Programming machines is a thing of the past.

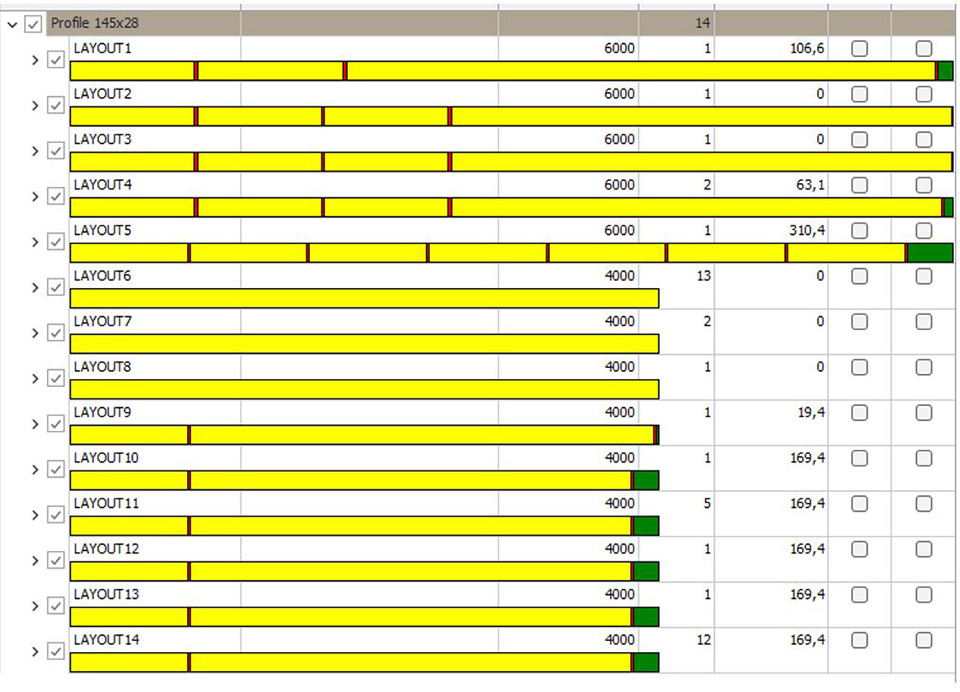

Example of optimisation

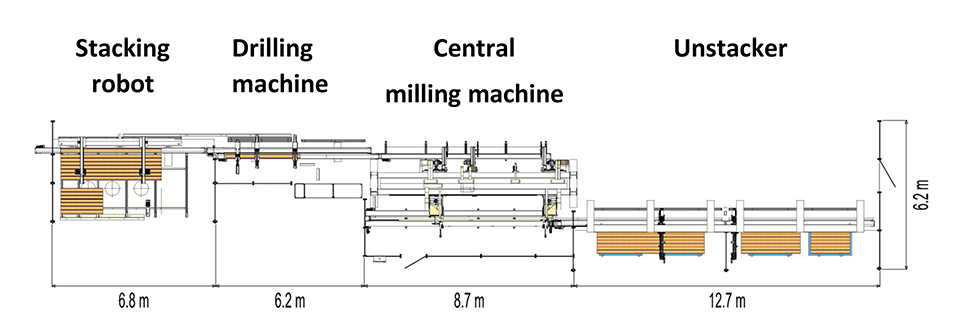

The heart is notch milling machine, which saws the logs to length, profiles the heads and makes the notches. This central notching machine can be extended with (automation) modules, which increases machine capabilities and reduces the workforce to zero.